Key Prototyping, Testing & Validation Services

Abotgeo offers an extensive range of cutting-edge prototyping, testing, and validation services to optimize product development and ensure compliance with industry standards.

RAPID PROTOTYPING – 3D PRINTING, CNC MACHINING, INJECTION MOLDING

Enables fast, precise model creation for design validation, functional testing, and manufacturing feasibility assessment.

STRUCTURAL & LOAD TESTING – STRESS, STRAIN, & FATIGUE ANALYSIS

Evaluates material strength, deformation, and durability under various loads to ensure structural reliability.

ENVIRONMENTAL & THERMAL TESTING – TEMPERATURE & CORROSION RESISTANCE

Simulates extreme operating conditions to verify resistance to heat, humidity, corrosion, and chemical exposure.

VIBRATION, SHOCK & IMPACT TESTING – DURABILITY & CRASHWORTHINESS EVALUATION

Assesses product performance under real-world dynamic conditions, preventing failure due to mechanical shocks or vibrations.

MATERIAL & PROCESS VALIDATION – QUALITY CONTROL & COMPLIANCE CERTIFICATION

Ensures optimal material selection and manufacturing process consistency for improved efficiency and longevity.

FUNCTIONAL TESTING – MECHANICAL, ELECTRICAL, & INTEGRATED SYSTEM TESTING

Validates system performance, integration, and functionality to confirm design effectiveness before mass production.

FAILURE MODE & EFFECTS ANALYSIS (FMEA) – RISK IDENTIFICATION & MITIGATION

Identifies potential failure points and weak links in design, improving safety and product reliability.

REGULATORY COMPLIANCE TESTING – API, ISO, & INDUSTRY STANDARDS VERIFICATION

Ensures adherence to international standards for quality, safety, and market approval across industries.

Rapid Prototyping – Transforming Concepts into Functional Models

Bridging the gap between design and production, rapid prototyping allows for quick iterations, design refinements, and early-stage performance assessments. Abotgeo employs cutting-edge fabrication techniques to create high-precision prototypes, ensuring seamless product development and accelerated market entry.

Enhancing Product Development with Rapid Prototyping

From concept validation to pre-production models, our rapid prototyping services enable fast design iteration, material testing, and functional assessments. This process reduces development costs, enhances manufacturability, and identifies potential design improvements before mass production.

Key Rapid Prototyping Methods:

3D Printing (Additive Manufacturing) – Layer-by-layer fabrication for complex geometries

CNC Machining – High-precision milling for metal and plastic prototypes

Injection Molding Prototypes – Scalable production-ready prototypes

Vacuum Casting – Cost-effective replication for small production runs

Sheet Metal Prototyping – Rapid fabrication of structural components

Testing & Validation – Ensuring Performance, Safety & Compliance

Testing and validation are critical to certifying a product’s functionality, durability, and adherence to industry regulations. Abotgeo conducts rigorous mechanical, environmental, and operational testing to ensure optimal performance in real-world conditions.

Optimizing Product Quality Through Advanced Testing

Our simulation-driven and physical testing methodologies eliminate defects, improve product reliability, and ensure regulatory compliance with API, ISO, and industry-specific standards. We provide comprehensive failure mode analysis, lifecycle durability assessments, and extreme condition testing to validate product safety and efficiency.

Key Testing & Validation Services:

Structural Load Testing – Assessing material strength and failure thresholds

Thermal & Environmental Testing – Simulating extreme operating conditions

Vibration & Shock Testing – Ensuring stability under dynamic loads

Fatigue & Lifecycle Testing – Predicting long-term performance and durability

Regulatory Compliance Testing – Ensuring adherence to industry standards

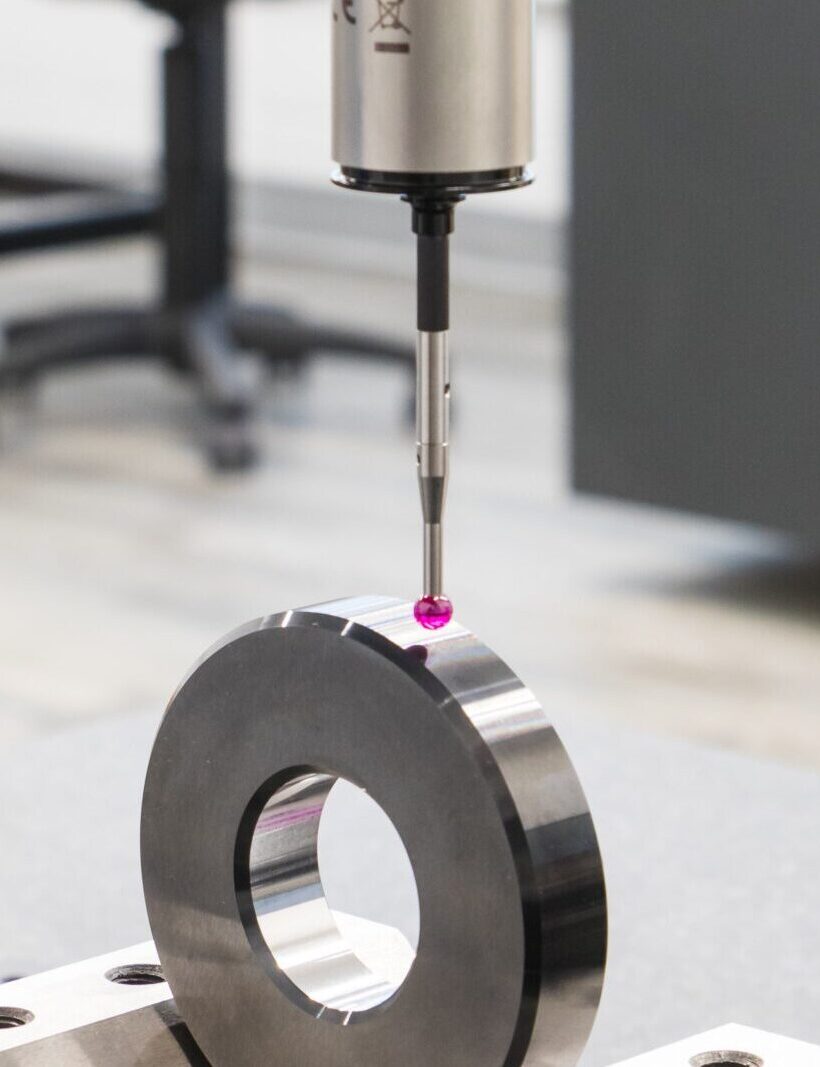

Material & Process Validation – Certifying Quality & Efficiency

Selecting the right materials and manufacturing processes is essential for product longevity, performance, and cost-effectiveness. Abotgeo offers material characterization, process optimization, and quality control testing to guarantee the highest standards in production.

Improving Reliability Through Material Validation

Our material testing services assess properties such as tensile strength, fatigue resistance, corrosion behavior, and thermal stability, ensuring products perform efficiently under operational stresses. Process validation ensures repeatable, defect-free production while optimizing manufacturing efficiency.

Key Material & Process Validation Services:

Material Property Testing – Analyzing mechanical and thermal properties

Corrosion & Chemical Resistance Testing – Ensuring environmental durability

Process Control & Repeatability Testing – Validating manufacturing consistency

Surface Finish & Coating Evaluations – Enhancing wear and corrosion resistance

Failure Analysis & Defect Detection – Identifying weak points and process inefficiencies

Functional & Performance Validation –

Real-World Reliability Testing

A product’s success depends on its ability to function as intended under operational conditions. Abotgeo’s functional validation services ensure mechanical, electrical, and software-integrated systems operate efficiently, safely, and reliably.

Enhancing Performance Through Rigorous Validation

Our comprehensive performance validation process verifies that products meet efficiency, safety, and reliability benchmarks. We use load simulations, real-world testing, and predictive failure analysis to confirm design excellence before full-scale production.

Key Functional Validation Services:

Mechanical & Structural Integrity Testing – Ensuring robustness under applied forces

Thermal Performance Validation – Confirming cooling efficiency and heat resistance

Load-Bearing & Pressure Testing – Verifying operational stress tolerance

Electromechanical System Validation – Testing integrated system functionality

Failure Mode & Effects Analysis (FMEA) – Identifying potential failure risks